Even before fuel costs exploded in early 2022, carriers in the trucking industry made steady efforts to increase the fuel efficiency of their fleets. Because it remains a major expense, finding ways to curb the cost of diesel remains a sensible long-term investment.

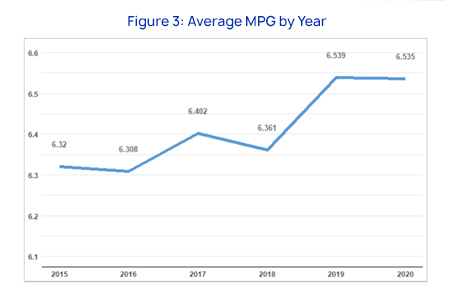

In the last few years, the average fuel efficiency of fleets has increased thanks to various eco-driving technologies.

Source: ATRI, An Analysis of the Operational Costs of Trucking: 2021 Update

Find out if your fleet has adopted any of the following five common strategies for bettering fuel efficiency.

1) Mechanical upgrades

A first source of fuel savings is the increased efficiency of truck OEMs. More efficient powertrains reduce the overall fuel consumption of trucks throughout their lifetime.

However, the acquisition of new tractors is too costly to be a fuel efficiency strategy by itself. At best, the replacement of older vehicles with newer models provides a gradual overall increase of efficiency over the long term.

Mechanical upgrades may also include various automatic idle reduction technologies to prevent fuel loss when the vehicle is not moving.

- Battery HVAC

- Diesel APU

- Automatic engine start/stop

- Fuel-operated heaters

- Solar panels

- Electronic engine idle parameters

- And more

Speed governors are another way to improve fuel consumption for fleets. This technology alone accounts for an improvement of almost 1 mpg in fuel economy, and ATRI reported that 81% of fleets in its study used fleet governors.

Read the complete fuel efficiency white paper

2) Aerodynamics

Over the years, fleets have increasingly improved tractor and trailer aerodynamics. These investments help reduce the air drag on vehicles, requiring less power to maintain their speed. These include:

- trailer skirts

- trailer tail

- aerodynamic mud flaps

- minimized gap between the trailer and the tractor

3) Power sources

The current crisis is a stark reminder of our dependency on fossil fuels until the heralded age of electric trucks arrives. Carriers have started to experiment with electric semis, but these have not yet become a mainstay.

In the meantime, other fuel types are used to replace standard diesel or biodiesel. According to ATRI, several fleets resort to compressed natural gas (CNG), liquefied natural gas (LNG) and liquefied propane gas (LPG). There has been an increase of these alternative fuel vehicles, yet, they account for an average of only about 6% of the fleet among carriers using them.

4) Operational improvements

Another way to save on fuel costs is to optimize fleet operations. In addition to the various savings that result, optimization also leads to streamlined routing and planning that cuts down on fuel consumption.

Ways to decrease mileage and running time of vehicles include:

- Reducing out-of-route miles

- Limiting detention time

- Avoiding traffic and weigh stations

- Using the most optimal route to decrease mileage

5) Driving behavior

There is a way to reduce fuel consumption regardless of truck make, model or year, fuel type, and without having to heavily invest in new equipment. Driver behavior can go a long way when it comes to fuel efficiency.

It’s no secret: some drivers perform better than others. All truck drivers are professionals, but some benefit from more training, experience, or just have better reflexes behind the wheel. Good driving translates into fewer accidents, intact loads on arrival, and fuel savings.

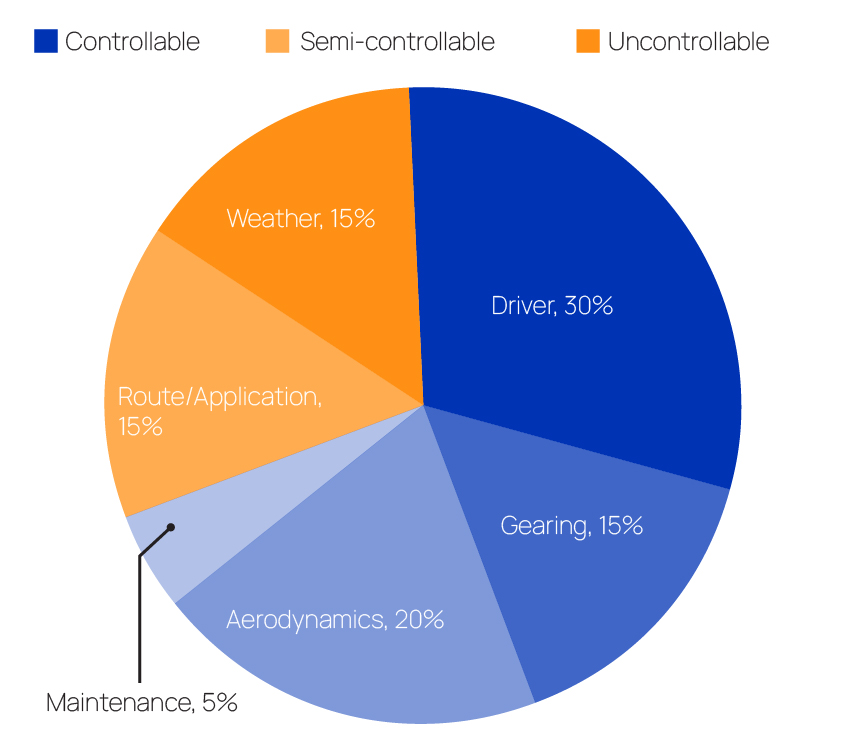

Up to 30% of fuel consumption directly comes from active decisions your drivers make. ATRI notes that more than 50% of fleets include eco-driving training as part of their fuel-saving strategy.

What could be even more effective than classroom training for improving driving behavior? ISAAC’s solution features real-time coaching as part of its in-cab technology. With ISAAC’s driver coaching, fleets may now implement both real-time fuel-efficient driving suggestions and a fair reward program based on reliable data.

Driver training for greater fuel efficiency

Of all the ways fleets can gain greater fuel efficiency, driver training is the most accessible and produces immediate results across the fleet.

However, teaching drivers the best eco-driving practices and having them care about it are two different things. Thanks to reliable data and fair scoring provided by ISAAC, our clients can successfully build incentive programs that boost their drivers’ engagement towards eco-driving and save up to 15% in fuel costs.

With the high cost of diesel these days, a fraction of these savings will make a huge difference to any carrier.